By definition, mica is a compound of silicate minerals that display similar physical and chemical composition. They are classified as principal rock-forming minerals.

Muscovite and Phlogopite are most common forms of mica used in commercial settings. The perfect basal cleavage attribute of micas allow the crystals to be split into very thin sheets that are tough and flexible.

Micas can either be found in large crystals or in the form of small grains. The large crystals can measure several meters. Mica grains, on the other hand, have shiny cleavage surfaces.

Micas form in distinct and flexible layers that are lightweight and heat-resistant. As such, mica does not conduct electricity.

The mica industry produces sheet mica as well as flake mica.

Sheet mica is painstakingly recovered primarily through open-pit surface mining of semi-hard pegmatite ore. A secondary method is to use air drills, hoists, and even small explosives to meticulously remove mica from the host rock.

There is significant cost involved in mining mica in the United States. Thus, countries such as China, India, Iran, and South Africa are more involved in mining due to lower labor costs.

On the other hand, flake mica is produced in the United States. The mining process involves the use of shovels, scrapers, and dozers to obtain soft mica deposits. Drilling and the use of explosives are involved in collecting hard-rock ore.

Mica: The Catalyst Behind Our Electric Future

Mica mining has long been a subject of interest the world over. In fact, the origins of mica mining can be traced back several centuries. At DataMica, we take pride in developing mica-based products that serve the needs of various industries. In fact, we have specialized in producing mica paper and mica sheets for well over 30 years.

In recent years, there’s been a renewed interest in mining mica, thanks to the great advancements in the auto industry. Mica is a key ingredient that drives the production of spark plugs. The electric vehicle industry is just one of several others that heavily rely on mica in order to manufacture high-performing products. Our company has long appreciated the role of mica and has extensive experience in manufacturing ultra-thin as well as reinforced mica paper, 3D mica laminate sheets, Phlogopite ceramic tape, and related mica-based specialized products.

Uses of Mica

Mica has several uses which makes it an ingredient of choice in different industries. Ground mica is used in building material as a filler and extender which lends a smoother consistency to gypsum wallboard joint compounds. Mica powder prevents cracking within the compound which adds to the longevity of the product.

The paint industry relies on ground mica to serve as a pigment extender. The lightweight nature of mica enables suspension, brightens the tone of colored pigments, and supports resistance to water damage. It also helps prevent weathering and shrinkage of paint film.

Mica is key to making electrical insulators due to its heat-resistant properties. It offers dielectric steadiness, capacitance stability, and lower power loss. Electric motors and generators, windows in stove and kerosene heaters, and lamp panels all use mica for insulation purposes.

The automotive industry also makes extensive use of mica to produce clutches and brakes. The thermal barrier provided by mica makes it the right choice because it helps facilitate heat transfers. Mica is non-flammable and can resist temperatures of up to 1000 degrees Celsius.

Mica: The Powerhouse Behind Smart, Self-Powered Devices

Wearable technology depends largely on self-powered devices that are flexible in order to resist deformation. They also take advantage of the tribe-electric effect which refers to contact electrification.

When two objects or materials come into contact and are forced to separate, the materials become electrically charged and carry static electricity that is tribe-electric in nature. For instance, when a balloon is rubbed against silk carpet, it becomes electrically charged and is able to attract hair.

Recently, there’s been an increased interest in producing thin and flexible tribe-electric nano generators that can be installed in wearable sensors, smart devices, and medical paraphernalia.

Here’s where mica comes into play. It has been isolated as a cheaper alternative to friction producing materials such as hydrogels and polymers. This positions it a great choice as a tribe-electric layer for nanogenerator devices of the future.

Mica and the Electric Vehicle Industry

As mentioned earlier, the automotive industry has long used mica in producing insulators and other components such as starters, alternators, clutches, and brakes. Mica is a durable and flexible compound which makes it the ideal choice for manufacturing automotive parts.

Today, electric vehicles (EV’s) have penetrated the automotive market. More and more people are interested in purchasing EV’s because of technological developments as well as the tremendous potential to reduce environmental pollution.

Moreover, with gas prices soaring to record heights, electric vehicles have seen a strong resurgence and are projected to take over a major chunk of the automotive industry.

The trend of adopting electric vehicles is not going to slow down. In fact, the production of super-capacitors improved lithium-ion batteries have propelled governments in several European countries to plan for hydrogen trains that are essentially fuel-cell powered.

Mica is used as a high-temperature incombustible barrier around electrically isolating battery packs as well as other components. The prominence of mica will only increase in order to meet the industry’s ever-changing performance challenges.

DataMica Products

At DataMica, we have harnessed the power of mica to produce revolutionary products since 1992. Our ultra-thin mica paper, reinforced mica paper, 3D mica laminate sheets, phlogopite ceramic tape and other mica-based special products are designed to meet and exceed the expectations of various industries.

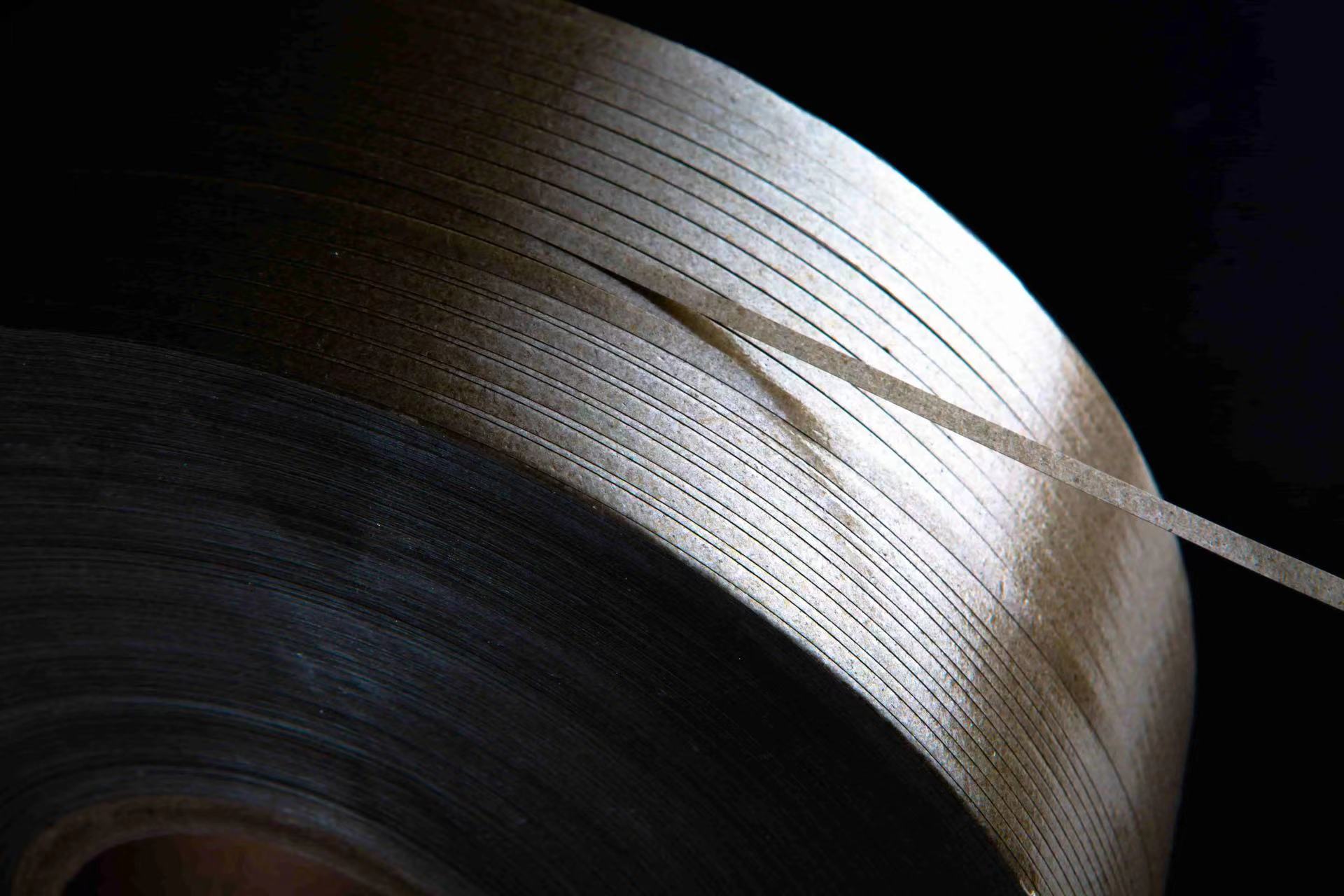

Mica Paper

Our mica paper is composed of high-quality Phlogopite mica materials that are bonded with high heat-resistant silicon resin. It is strong, flexible, resists high temperature, and has excellent insulating properties. Our mica paper is known for its low thermal conductivity and is available in multiple structural options.

3D Mica Sheet

At DataMica, we treat our mica sheets at 1200 degrees Celsius for 120 minutes. As a result, we are able to produce smooth and strong mica sheets that meet the needs of electric power, petrochemical, railway, construction, automotive and related industries.

Phlogopite Ceramic Tape

We use glass fiber reinforcement technology to produce our Phlogopite ceramic tape. Our mica tape fire-proof and can be used in combination with various plastics as well as silicon rubber. The resistance to high temperatures offers superior surface coating technology which makes our tape suitable for generator fields and armature coils.

Thermal Insulation

Mica is dielectric, meaning it is a very poor conductor of electricity. Mica is noncombustible which makes mica-based insulation resist temperatures of up to 1600 degrees Celsius. That is why at DataMica we are able to producing thermal insulation that can withstand high voltages and minimize the risk of fire.

If you would like to find out how our products can help you, please contact us today.