Mica Tape

Phlogopite Mica Tape

DataMica’s phlogopite mica tape is a high temperature and fire resistant product which has undergone 76 production control points, failure mode effect analysis and strict pre-delivery quality inspections. As a result, we have created a series of DataMica’s products under the name of HiResistTM brand.

As one of the mature mica tape manufacturers, we have carried out research & development and testings of electrical, thermal, mechanical as well as other technical parameters of HiResistTM brand phlogopite mica tape in our Shanghai R&D center. These mica insulation tapes are produced in China’s Sichuan Ya’an Mica Co. Ltd, and finally delivered to the world’s customers who pursue product quality in the fields of fire resistant optical fibers, control Cable, EV BUSBAR and high temperature insulation applications. We are proud that Prysmian, Nexans, LG and other famous cable companies use our products for their fire-resistant protective materials.

Control of Key Raw Materials for Phlogopite Mica Tape

The production control measures of DataMica’s HiResistTM Phlogopite tape has been taken place from the very beginning, i.e. screening of mica mineral ore scraps. After more than 30 updates of the quality requirements and delivery inspection standards of the mineral ore scraps in Madagascar, Africa, we have formed quality standards of the key raw materials, including sampling methods and standards.

Phlogopite Pulp Quality Control

Phlogopite mineral scraps is delivered to our Ya’an factory after 2 months of sea and land transportation, and then we have to do a warehouse quality inspection.

Afterwards, we, professional in mika tape, start to make phlogopite paper pulp according to the production schedule. In this important step, the scraps will be cleaned by high pressure water jets and remove fine sands which may affect the dielectric strength.

Through our special pulping machine, we crush mica into micron-level thickness, and control the aspect ratio of micron-level mica fragments in order to produce phlogopite paper pulp with perfect aspect ratio.

Production Control of Glass Fiber Reinforced Material for Phlogopite Tape

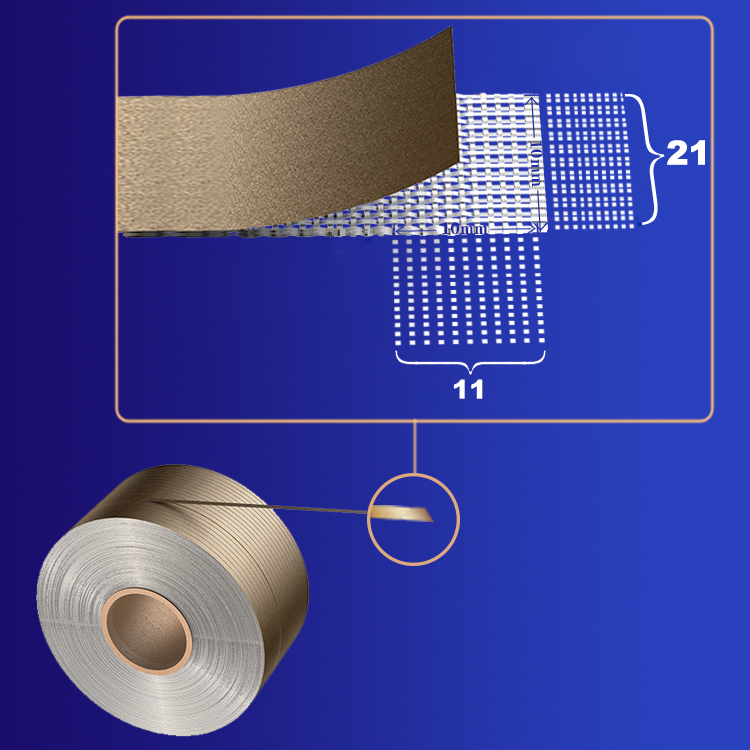

We have 30 years of experience in mica composite materials. The starting point of our experience was to manufacture glass fiber reinforced materials. As one of the high-quality mica tape suppliers, we have been supplying glass fiber reinforced materials to mica-related manufacturers in China for over 30 years. With Special understanding of reinforcement requirements, we have the best glass fiber cloth design in terms of thread counts. Within one square centimeter, thread counts in both warp and weft directions are major factor which affects the strength of the glass fiber cloth. We use thread counts of 23×11 (warp x weft) for our glassfibre cloth, whereas, most manufacturers use as low as 50% of our thread counts per unit area in order to save costs.

Production Control of Glass Fiber Reinforced Material for Phlogopite Tape

We have 30 years of experience in mica composite materials. The starting point of our experience was to manufacture glass fiber reinforced materials. We have been supplying glass fiber reinforced materials to mica-related manufacturers in China for over 30 years. With Special understanding of reinforcement requirements, we have the best glass fiber cloth design in terms of thread counts. Within one square centimeter, thread counts in both warp and weft directions are major factor which affects the strength of the glass fiber cloth. We use thread counts of 23×11 (warp x weft) for our glassfibre cloth, whereas, most manufacturers use as low as 50% of our thread counts per unit area in order to save costs.

Processes of Composite and Cutting of Phlogopite Paper Rolls into Tapes

The composite production line of phlogopite paper and glass fiber cloth developed by us is 40 meters longer than the traditional one in the market. Through sufficient chemical cross-linking reactions with other composite materials, it lays the foundation for us to innovate more new mica cable tape materials.

Find out more about our mica tape solutions and how they could help you increase infficiency and safety.

Find out more about our mica tape solutions and how they could help you increase infficiency and safety.

Ask Us Anything. Anytime.

DataMica engineers take on tough problems across high temperature insulation.

Boston

- 400 Trade center Drive Suite 5900, Woburn, MA01801

- +1 (206)423-7079