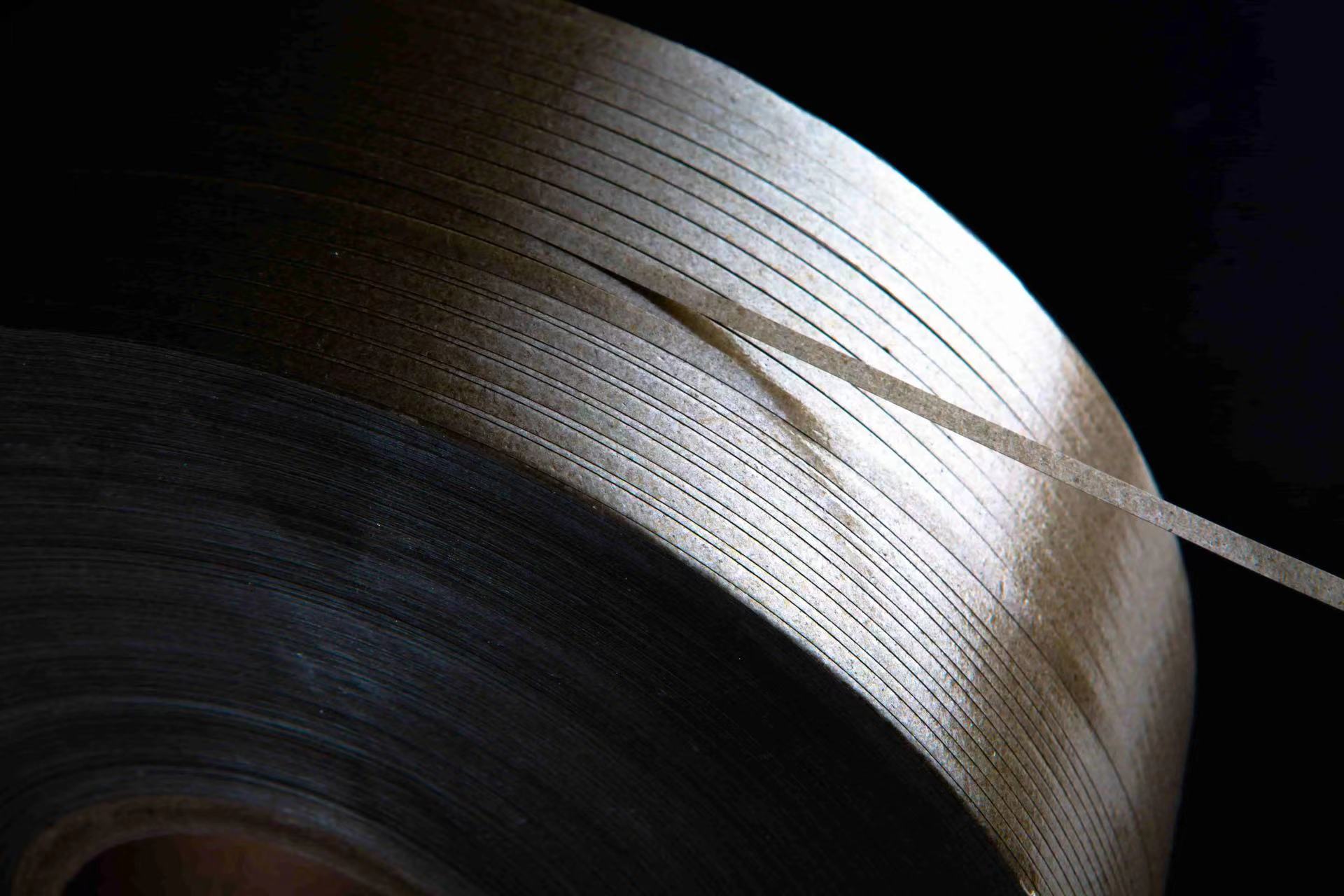

The insulation layer of power cable is composed of paper, oil, linen, rubber, plastic, asphalt and other combustible materials. Therefore, the cable has the possibility of fire and explosion. The cause of cable fire and explosion is:

(1) short circuit fault caused by insulation damage. The protection of power cable is damaged during laying, or the cable insulation is damaged by mechanical damage during operation, which leads to insulation breakdown between cables or lead sheath. The arcing causes the insulation material and cable outer protective layer material to burn.

(2) long time overload operation of cables. The operation temperature of cable insulation material exceeds the maximum allowable temperature of normal heating, which makes the cable insulation aging and dry. This kind of insulation aging and drying phenomenon usually occurs on the whole cable line. Because the cable insulation aging and drying, insulation materials lose or reduce insulation performance and mechanical properties, it is prone to breakdown, ignition, combustion, and even along the entire length of the cable burning at the same time in many places.

(3) the oil immersed cable is leaking due to the height difference. When the oil cable is installed with a high difference, the cable oil flowing phenomenon may occur. As a result of the flow, the upper part of the cable dries up because of the loss of oil. The thermal resistance of the part of the cable increases, causing the breakdown of the paper insulation. In addition, as the upper oil drips down, space is released at the upper cable head and negative pressure is generated to allow the cable to absorb moisture and damp the end. The lower part of the cable causes great static pressure due to the accumulation of oil, which makes the cable head leak. Cable wetting and oil leakage also increase the probability of failure fire.

(4) insulation breakdown of intermediate junction box. The cable connector box joints by crimping tight, welding joint is not strong or improper material selection, joint oxidation, fever, gummosis in operation; in cable joints, insulation agent perfusion quality does not meet the requirements in the middle of the connector box, filling insulating agent, memory box has pores and cable box seal bad, damaged and leaking into the moisture, the above factors can cause insulation breakdown, a short circuit of the cable fire explosion.

(5) cable head combustion. Due to the contamination of the cable head surface, the rupture of the cable head bushing and the small distance between the outgoing lines, resulting in flashover and fire, leading to the insulation of the cable head surface insulation and the insulation of the lead out line.

(6) external fire source and heat source lead to cable fire. For example, the fire spread of oil system, the explosion of oil circuit breaker fire, the spontaneous combustion of pulverized coal in boiler pulverizing system or coal handling system, the baking of high temperature steam pipe, the chemical corrosion of acid and alkali, welding sparks and other fire materials can cause fire in cable.

Conclusion

Therefore, regular checks and maintenance along these causes are required to prevent cable fire and explosion, consequently reduce losses of property and even lives.