Mica tape includes mica paper layer and reinforcing material layer, with burnable inorganic compounds mixed in either layer, making it a type of fire-resistant insulating material.

By purpose, it can be classified as mica tape for motors or mica tape for cables.

By structure, it can be classified as double-sided tape, single-sided tape, three-in-one tape, double film tape, single film tape, etc.

By type of mica, it can be classified as synthetic mica tape, golden mica tape, and white mica tape.

Fire-resistant and safe mica tape for cables is a high-performance mica insulating product with excellent high-temperature and combustion resistance properties.

Performance of mica tape

At room temperature, the performance is best for synthetic mica tape, followed by white mica tape and then golden mica tape. Under high temperature, the insulation performance is best for synthetic mica tape, followed by golden mica tape and then white mica tape.

High-temperature and combustion resistance performance: Synthetic mica tape with fluoride and gold mica tape, without crystal water and with a melting point of 1375℃, has the best high-temperature resistance performance and a large safety margin. Golden mica releases crystal water above 800℃, and has slightly worse high-temperature resistance performance. White mica releases crystal water at 600℃ and has poorer high-temperature resistance performance.

The performance is also related to the degree of mica tape’s compounding.

Fire-resistant cables with mica tape

Fire-resistant and safe mica tape is a high-performance mica insulating product with excellent high-temperature and combustion resistance properties. Fine mica tape is flexible in normal conditions and is suitable for the main fire-resistant insulation layer in various fire-resistant cables. When burned in flames, harmful smoke is not released, so this product is not only effective for cables but also very safe.

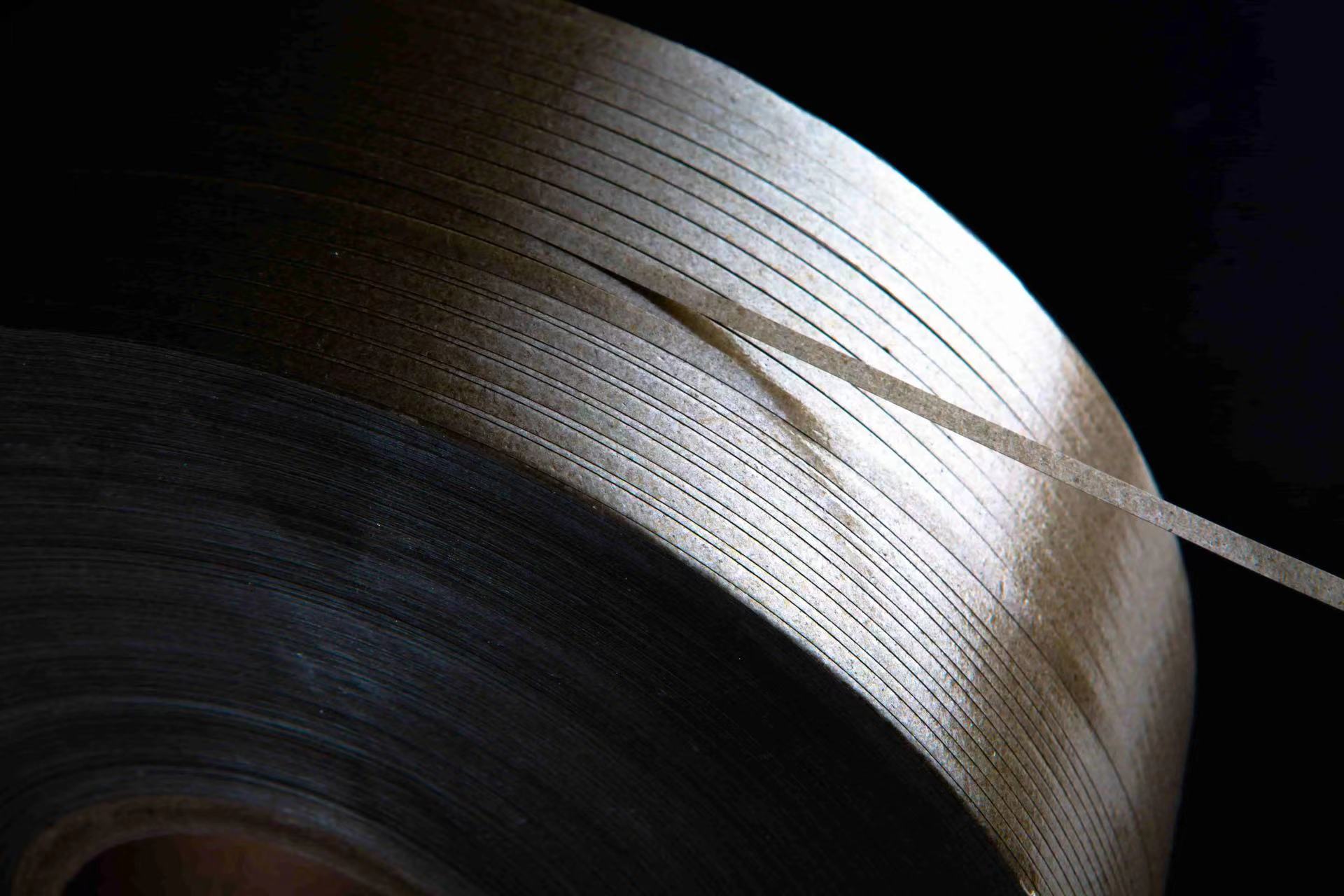

Synthesis of mica tape

Synthetic mica is a man-made mica with large dimensions and complete crystal type, which is synthesized under normal pressure by replacing hydroxyl groups with fluoride ions. Synthetic mica tape is made by machine using synthetic mica paper as the main material and sticking glass cloth on one or two sides with adhesive. The one with glass cloth adhered to one side of mica paper is called “single-sided tape,” and the one with glass cloth adhered to both sides is called “double-sided tape.” During the production process, several structural layers are bonded together, and then dried in a furnace, rolled up, and then cut into tapes of different specifications.

In addition to the characteristics of natural mica tape, including small expansion coefficient, large dielectric strength, high resistivity, and uniform dielectric constant, synthetic mica tape has the main feature of high heat resistance level, reaching A-level fire resistance (950-1000℃). Synthetic mica tape has a high temperature resistance of greater than 1000℃, a thickness range of 0.08-0.15mm, and a maximum supply width of 920mm.

- Three-in-one: This product is a strip-shaped insulating material made of glass cloth and polyester film on both sides, sandwiching fine mica paper in the middle. An amino-borane-epoxy resin is used as the adhesive, bonded and baked before being cut;

- Double-sided synthetic mica tape: Using synthetic mica paper as the substrate, reinforced with glass fiber cloth on both sides and bonded with silica resin adhesive, it is the most ideal choice of material for manufacturing fire-resistant wires and cables. It has the best fire-resistant performance, recommended for use in key projects.

- Single-sided synthetic mica tape: Using synthetic mica paper as the substrate, reinforced with glass fiber cloth on one side, it is the most ideal choice of material for manufacturing fire-resistant wires and cables. It has good fire-resistant performance, recommended for use in key projects.