Industrial furnaces play a crucial role in various manufacturing processes, where extreme heat is required. To ensure optimum efficiency and safety in these high-temperature environments, the choice of suitable materials is of paramount importance. Among these materials, high temperature mica sheets supplied by the renowned brand DataMica have emerged as a versatile solution, revolutionizing the performance of industrial furnaces. In this blog post, we delve into the unique characteristics and numerous applications of high temperature mica sheets, shedding light on their exceptional benefits and limitations.

Understanding the Importance of High Temperature Mica Sheets

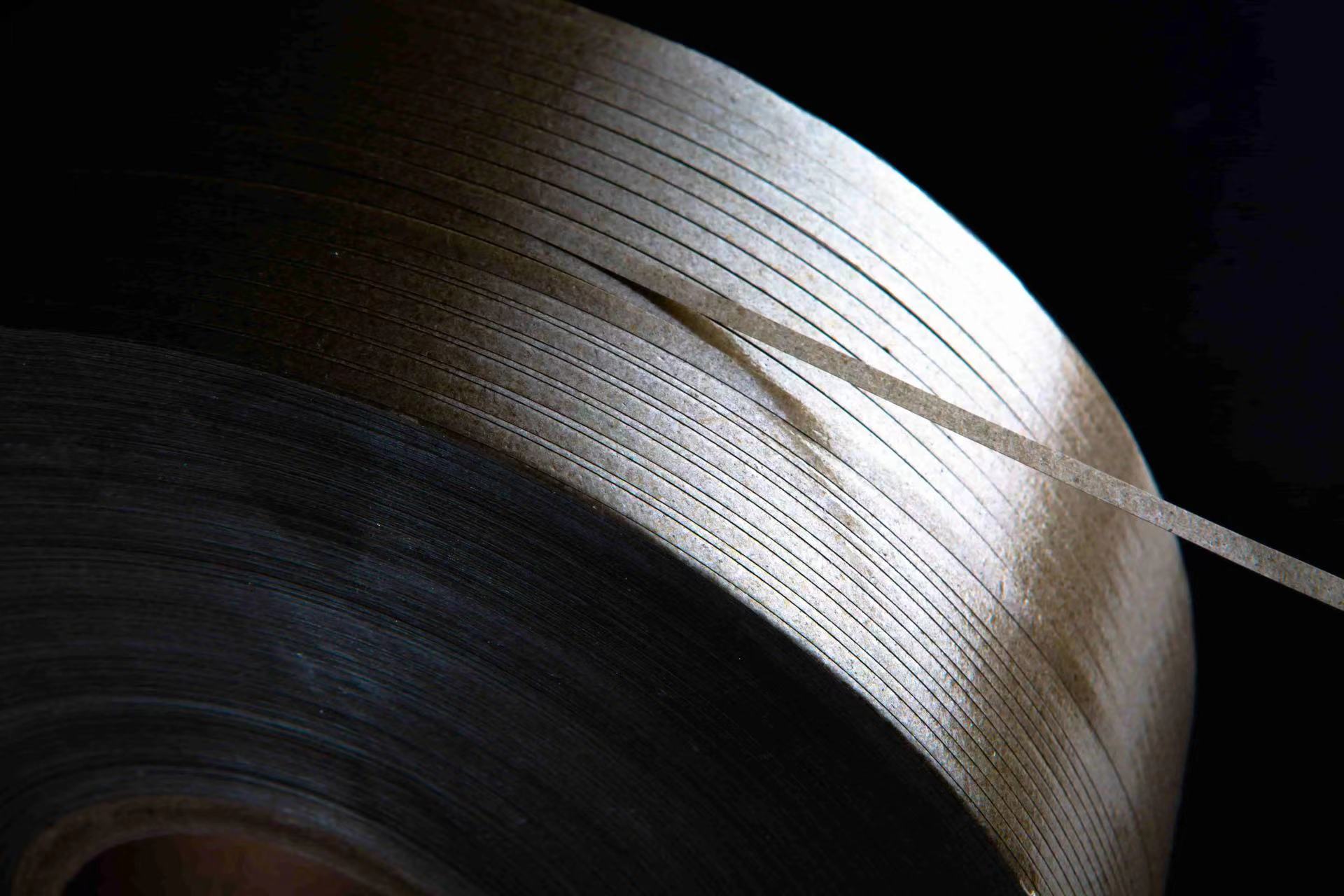

High temperature mica sheets are composed of phlogopite or muscovite mica, impregnated with a selected temperature-resistant silicone binder. This unique combination results in a material that can withstand high temperatures ranging from 500 to 1000°C, making it ideal for industrial furnace applications. The exceptionally high thermal conductivity of mica sheets allows for effective heat transfer, ensuring improved energy efficiency in industrial furnaces.

Applications of High Temperature Mica Sheets in Industrial Furnaces

The versatility of high temperature mica sheets makes them indispensable in a multitude of applications within industrial furnaces. These sheets are commonly used as insulation material for various heating elements, such as resistance wires, heating coils, and thermocouples. Their ability to resist intense heat and possess exceptional electrical insulation properties ensures the safety and reliability of the furnace.

Additionally, high temperature mica sheets find extensive usage in thermal barriers, gasketing, and sealing applications. Their ability to withstand extreme temperatures effectively prevents heat loss, reduces energy consumption, and improves overall furnace performance. Furthermore, these sheets can also be used in furnace linings to protect against thermal shocks, ensuring the longevity and durability of the furnace structure.

Advantages and Limitations of High Temperature Mica Sheets

One of the key advantages of high temperature mica sheets is their inherent flexibility and ease of use. They can be easily fabricated, cut, and molded into the desired shape, allowing for customized solutions to fit a wide range of industrial furnace configurations. This flexibility ensures efficient utilization of the available space while maintaining optimal heat distribution.

However, it is crucial to consider the limitations of high temperature mica sheets. Although highly heat-resistant, prolonged exposure to temperatures exceeding their specific limitations may result in performance degradation. Proper assessment and selection of the appropriate mica sheet variant are essential to ensure long-term reliability and safety.

Maximizing Efficiency and Performance in Industrial Furnaces with High Temperature Mica Sheets

The utilization of high temperature mica sheets, such as those provided by DataMica, brings numerous benefits to industrial furnace operations. Their remarkable combination of heat resistance, electrical insulation, and thermal conductivity allows for enhanced energy efficiency, improved productivity, and extended lifespan of the furnaces. By understanding the advantages and limitations of high temperature mica sheets, engineers and manufacturers can harness their versatility to revolutionize their industrial heating processes.

In conclusion, high temperature mica sheets have undoubtedly emerged as a game-changer in the field of industrial furnace applications. DataMica’s commitment to providing high-quality mica sheets ensures that industrial furnaces can operate at peak performance, with utmost efficiency and safety. These remarkable materials continue to transform the heat harnessing capabilities of industrial furnaces, contributing significantly to advancements in various manufacturing sectors.