Definitions

- the present invention

relates to a coil for an electric rotating machine, which is configured by forming an insulation layer on the periphery of a conductor, and mica tape and a mica sheet used for the coil insulation. - a plurality of slots 1 a

are formed on the inner surface of stator core 1 . - the each slot 1 a

accommodates a stator coils 2 . - the stator coils 2

comprise an upper coil and a lower coil. To accommodate the upper and lower coils into the slot, insulation spacers 3 are inserted into the bottom of the slot 1 a , between the upper and lower coils, and into the opening of the slot 1 a. - a slot wedge 4 for securing the stator coil 2

is inserted in the open end of the slot 1 a . - the slot wedge 4

suppresses the stator coil 2 vibration generated from electromagnetic pulsating force due to load current in the conductor. - the stator coil 2 accommodated in the slot 1 a of the stator core 1

is formed of a conductor that has the following structure. - a plurality of insulated square strands 21

are bundled and Roebel-transposed. - pre-preg separator 11 with thermosetting resin

is arranged between a strand bundle 30 a on the left side row in the figure and a strand bundle 30 b on the right side row in the figure. - Pre-preg filler 12 with thermosetting resin

is arranged on the Roebel-transposed portion on top and bottom of the strand bundles 30 a and 30 b. - thermosetting resin in the pre-preg separator 11 and that of the pre-preg filler 12

are heated and cured while the strand bundles 30 a and 30 b are integrally molded in one piece by heat pressing. - a conductor 22

is finished to finally have a section as shown in the figure by heating and curing the pre-preg separator 11 and pre-preg filler 12 . - the conductor 22

is insulated by the following process called vacuum pressurized impregnation system with thermosetting resin. - a mica tape 7

which includes mica paper 5 and glass cloth backing 6 as shown in FIG. 2 , is wound a plurality of layers around the conductor 22 . - Thermosetting resin

is impregnated into the wound layers of the mica tape 7 under vacuum pressurized condition. After that, the thermosetting resin and the mica tape 7 are heated and cured by heat pressing while the stator coil 2 is molded to so as to have a final section. - An insulation layer 8

is formed on the periphery of the conductor 22 by heating and curing the thermosetting resin and the mica tape 7 . - the conductor 22

In the stator coil 2 so configured, the conductor 22 generates heat by load current at the time of the operation of the electric rotating machine. Part of the generated heat is transmitted to the environmental cooling gas directly from ventilation ducts, which are arranged on the cross section of the stator core 1 at appropriate intervals in the axial direction, through the insulation layer 8 . Most of the remaining generated heat is transmitted to the stator core 1 through the insulation layer 8 and then indirectly to the environmental cooling gas. When the generated heat is thus transmitted to the cooling gas, all the heat generated from the conductor 22 is cooled via the insulation layer 8 of the stator coil 2 . From these points of view, the thermal conductivity along the heat passage is very important. - the thermal resistance along the heat passage

is high, the heat generated in the conductor 22 will be hard to transmit to the cooling gas and thus the temperature of the stator coil 2 will increase to excess. - the excessive temperature rise

accelerates the deterioration of electrical and mechanical performance of organic materials in the insulation layer 8 as the electric rotating machine is operated for a long time. - the above insulation layer 8

includes mainly mica paper 5 , glass cloth backing 6 , thermosetting resin, etc. - the thermal conductivity of mica

is about 0.5 W/m.K, that of glass is about 1.0 W/m.K, and that of epoxy resin, which is a typical thermosetting resin, is about 0.2 W/m.K. - thermosetting resin

In order to improve the thermal conductivity of the insulation layer 8 , therefore, it is effective to reduce the volume of thermosetting resin with the lowest thermal conductivity. - the impregnated thermosetting resin

can easily be detained in the texture of the glass cloth backing 6 and in the mica paper 5 . - the measures adopting a very thin glass cloth backing 6

squeeze out the impregnating resin by applying an appropriate molding pressure at the time of heating and curing, and the like are taken. - inorganic particles

such as aluminum oxide and boron nitride having higher thermal conductivity than that of the resin are mixed with mica flakes together with synthetic fibers such as polyamide fibers. - the inorganic particles so used

each have a diameter of 30 ⁇ m to 100 ⁇ m. - the synthetic fibers

serve as a reinforcement member for the mixed mica paper. - the inorganic particles of high thermal conductivity

are arranged not only in the mica paper but also between layers of the mica tape 7 . - a so-called pre-preg mica tape that is pre-impregnated with a resin containing inorganic particles

is wound around a conductor and then heated and cured in a molding jig. - a so-called pre-preg mica tape that is pre-impregnated with a resin

is coated with inorganic particles on its surface and wound around a conductor. After that, it is heated and-cured in a molding jig. - a thin insulation tape coated with inorganic particles

is wound around a conductor, together with a mica tape, to form a main insulation layer. - the inorganic particles

are buried and dispersed in the mica paper. - the inorganic particles and the synthetic fibers

make slits in the mica paper. - the slits formed by the inorganic particles

facilitate the resin impregnation. - the slits formed by the inorganic particles that are present in the insulation layer provided on the peripheral surface of the conductor

decrease the electrical strength. - the methods (2) and (3)

are so-called pre-preg insulation system using a pre-preg mica tape. If these methods were introduced to the vacuum pressurized impregnation system, the following peculiar problems will arise. - the mica flakes

are adhered each another, and mica paper and glass cloth backing are also adhered with a minimum amount of adhesive. - the adhesive

must be dissolved with the impregnating resin during the impregnation process and they must be formed integrally as a main insulation wall through heat curing. Consequently, the adhesive is required to have mutual dissolubility with the impregnated resin. If, therefore, the impregnated resin is, for example, epoxy resin including a curing agent, the epoxy resin (which may contain an accelerator) is generally selected as an adhesive. - the squeeze-out of the inorganic particles

increases as a molding pressure force to squeeze out an excess impregnated resin from the insulation layer. - the tendency of flow of the inorganic particles

is more conspicuous in a system that is impregnated with a low-viscosity, high-solubility resin and molded at a high pressure. - a coil for an electric rotating machine, and mica tape and a mica sheet used for the coil insulation

are configured as follows. - a coil for an electric rotating machine

is configured by bundling a plurality of square strands, stacking the square strands like a coil with Roebel transposition, winding mica tape which is made up of mica paper and glass cloth backing, a plurality of mica tape layers around the conductor, and impregnating and curing resin between wound layers of the mica tape to form an insulation wall. - Inorganic particles

are supported by the mica tape using an adhesive containing glue insoluble in the impregnated resin as a component. - Mica tape used for a coil insulation of an electric rotating machine

comprises mica paper and glass cloth backing. Inorganic particles are supported with the glass cloth backing using an adhesive containing glue insoluble in impregnating resin as an indispensable component. - a mica sheet used for a coil insulation of an electric rotating machine

comprises mica paper and glass cloth backing. Inorganic particles are supported with the glass cloth backing using an adhesive containing glue insoluble in impregnating resin as an indispensable component. - FIG. 1

is a sectional drawing of a stator coil accommodated in a stator core slot of a high-voltage electric rotating machine. - FIG. 2

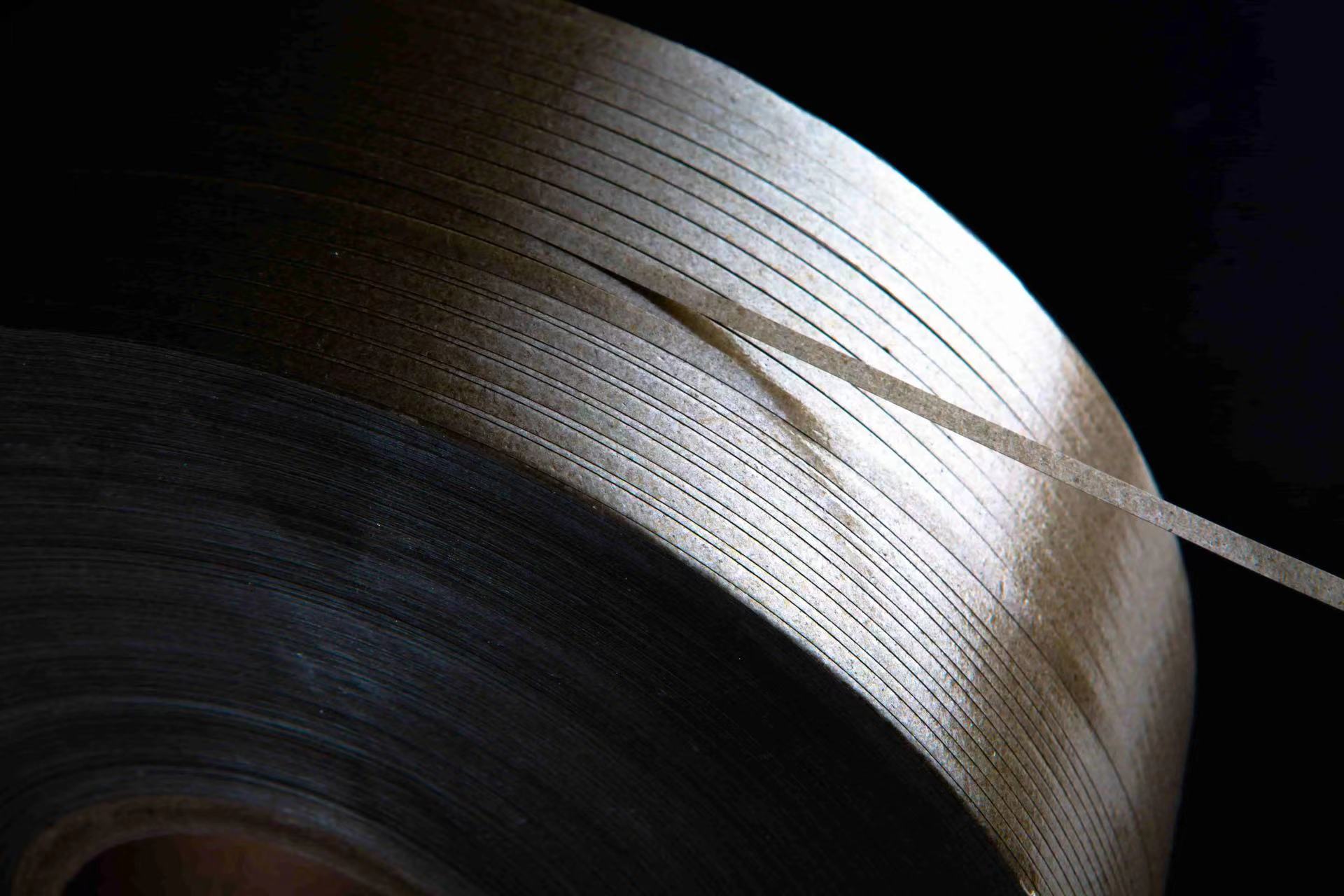

is a sectional drawing showing mica tape that makes up an insulation wall formed on the periphery of a conductor of a conventional stator coil. - FIG. 3

is a sectional drawing showing mica tape (mica sheet) for explaining the first to third embodiments. - FIG. 4

is a graph showing measurement results of impregnating time of an insulation wall according to the first embodiment. - FIG. 5

is a graph showing the weight percentage of inorganic particles flowing out from the insulation wall according to the first embodiment. - uncalcinated muscovite mica tape 71

having a structure as shown in FIG. 3 is wound a plurality of layers around the conductor 22 . - the uncalcinated muscovite mica tape 71

comprises mica paper 5 and glass cloth backing 6 . - Inorganic particles 14

are supported with the glass cloth backing 6 of the mica tape 71 using an adhesive 13 . - the adhesive 13

contains glue that is insoluble in impregnating resin as an indispensable component. - an adhesive 13 containing 4 wt % of polyvinyl alcohol

is used as a polyvinyl-based polymer that produces the effect of supporting the inorganic particles 14 . - 30 wt % of aluminum oxide particles of mica tape

are used as the inorganic particles 14 . - an epoxy resin composition

for example, Epikote 828 or 1001 manufactured by Yuka-Shell Co., Ltd., which has mutual dissolubility with the impregnating resin, is used in addition to the polyvinyl alcohol. - thermosetting resin

After a thermosetting resin is impregnated into the mica tape layers 71 under vacuum pressurized condition, it is heated and cured by heat pressing at a pressure of 0.5 MPa while the insulation layer 8 is formed so as to have a final section. - the impregnating resin

is, for example, a composition comprising a 45 wt % of cycloaliphatic epoxy compound, a 45 wt % of acid anhydride curing agent, and a 10 wt % of reactive diluent. - This impregnating resin

has a low viscosity of about 40 mPa. ⁇ s at room temperature. - the uncalcinated muscovite mica tape 71 of the present embodiment

in which only the additional amount of polyvinyl alcohol is changed, is wound a plurality of layers around the conductor 22 to form an insulation wall 8 having a final thickness of, e.g., 5 mm. - the conductor 22 on which the insulation layer 8 is formed with the mica tape 71

is submerged in the impregnating resin and applied a pressure of, e.g., 0.7 MPa in the tank after vacuum treatment. - FIGS. 4 and 5

are graphs showing results of the measurements. - the impregnation time

is suddenly lengthened when the amount of additional polyvinyl alcohol exceeds 5 wt %. This is because the polyvinyl alcohol forms a film barrier and inhibits the impregnating resin from being impregnated. - polyvinyl alcohol

is added favorably in an additional amount between 0.5 wt % and 5 wt % as glue included in the adhesive 13 , and the inorganic particles 14 are supported with the mica tape 71 . - the above amount of additional polyvinyl alcohol and the supporting effect thereof

exclude the influence of a long-time resin impregnation, and the inorganic particles 14 can be prevented from flowing out of the insulation layer 8 ; therefore, the thermal conductivity can be improved. - the supporting effect of polyvinyl alcohol

prevents the flowing out of the inorganic particles 14 with impregnated resin from the insulation wall 8 even when the heat pressing is applied to form a final section. - the thermal conductivity of the insulation wall 8

is improved and secondarily the falling of the inorganic particles 14 when the mica tape is wound can be decreased. Since, furthermore, the polyvinyl alcohol is added in an appropriate amount, the influence of a long-time impregnation can be lessened. - the thermal conductivity of a heat pass from the conductor to the cooling gas

is increased, so that the temperature rise of the stator coil can be decreased and the machine can be decreased in size. - An uncalcinated muscovite mica tape 71 with the adhesive 13

is wound a plurality of layers around a conductor 22 . - the uncalcinated muscovite mica tape 71

is formed with supporting inorganic particles 14 of boron nitride particles on a glass cloth backing 6 . - an epoxy resin composition

for example, Epikote 828 or 1001 manufactured by Yuka-Shell Co., Ltd., which has mutual dissolubility with the impregnating resin, is used in addition to the polyvinyl butyral. - the wound layers of the mica tape 71 under vacuum pressurized condition

is heated and cured by heat pressing at a pressure of, e.g., 0.5 MPa while a stator coil 2 is formed to a final section. - An insulation wall 8

is formed on the periphery of the conduct 22 due to the heating and curing of the thermosetting resin in mica tape 71 . - the impregnating resin

is a composition comprising a 45 wt % of cycloaliphatic epoxy compound, a 40 wt % of acid anhydride curing agent, and a 15 wt % of reactive diluent as disclosed in Jpn. Pat. Appln. KOKAI Publication 11-345733. - This impregnating resin

has a low viscosity of about 30 mPa. ⁇ s at room temperature. - the second embodiment

can also attain the same advantage as that of the first embodiment. - a uncalcinated muscovite mica tape 71 with the adhesive 13

is wound a plurality of layers around a conductor 22 . - the uncalcinated muscovite mica tape 71

is formed with supporting inorganic particles 14 of aluminum nitride particles on a glass cloth backing 6 . - an epoxy resin composition

for example, Epikote 828 or 1001 manufactured by Yuka-Shell Co., Ltd., which has mutual dissolubility with the impregnating resin, is used in addition to the polyvinyl formal - thermosetting resin

After a thermosetting resin is impregnated into the wound layers of the mica tape 71 under vacuum pressurized condition, it is heated and cured with heat pressing at a pressure of 0.5 MPa while a stator coil 2 is formed so as to have a final section. Due to the heating and curing of the thermosetting resin and mica tape 71 , an insulation layer 8 is formed on the periphery of the conductor 22 . - the impregnating resin

is a composition comprising a 45 wt % of cycloaliphatic epoxy compound, a 40 wt % of acid anhydride curing agent, and a 15 wt % of reactive diluent as in the second embodiment. - This impregnating resin

has a low viscosity of about 30 mPa. ⁇ s at room temperature. - the third embodiment

can also attain the same advantage as that of the first embodiment. - aluminum oxide

Al 2 O 3 - boron nitride

BN - aluminum nitride

AlN - BeO

beryllium oxide - MgO

magnesium oxide - SiC

silicon carbide - one of polyvinyl alcohol, polyvinyl butyral and polyvinyl formal

is used as glue contained in the adhesive. - At least two of polyvinyl alcohol, polyvinyl butyral and polyvinyl formal

can be used as the glue. - a polyvinyl-based polymer

is used as the glue. - the mica tape 71

is not limited to the first to third embodiments. Needless to say, the mica tape 71 can be applied to the insulation for a rotator coil of an electric rotating machine. - the mica tape 71

also includes a mica sheet 72 that is formed like a sheet. - the high thermal-conductivity inorganic particles 14

are arranged on the mica tape 71 (mica sheet 72 ) and supported on the mica tape 71 ( 72 ) using the adhesive 13 containing glue insoluble in the impregnating resin. Therefore, the inorganic particles 14 do not flow out, by virtue of the supporting effect of the glue, even in the process of squeezing the impregnated resin with heat pressing and then forming the insulation wall 8 to a final section. Consequently, the effect of improving the thermal conductivity of the insulation wall 8 is conspicuous and the influence of the glue on the impregnating time can be lessened. - the backing base material combined with the mica paper 5

is not limited to the glass cloth backing 6 . - a cloth-like base material, such as polyester cloth, aramid cloth and alumina cloth

has only to be used as the backing base material of the mica tape 71 (mica sheet 72 ). - a high-efficiency electric rotating machine

is achieved with a stator coil that is sufficiently improved in thermal conductivity.

Images (3)

Classifications

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02K—DYNAMO-ELECTRIC MACHINES

- H02K3/00—Details of windings

- H02K3/30—Windings characterised by the insulating material

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02K—DYNAMO-ELECTRIC MACHINES

- H02K3/00—Details of windings

- H02K3/32—Windings characterised by the shape, form or construction of the insulation

- H02K3/34—Windings characterised by the shape, form or construction of the insulation between conductors or between conductor and core, e.g. slot insulation

- H02K3/345—Windings characterised by the shape, form or construction of the insulation between conductors or between conductor and core, e.g. slot insulation between conductor and core, e.g. slot insulation

Landscapes

- Engineering & Computer Science

(AREA) - Power Engineering

(AREA) - Insulation, Fastening Of Motor, Generator Windings

(AREA) - Insulating Bodies

(AREA)

Abstract

Description

CROSS-REFERENCE TO RELATED APPLICATIONS

BACKGROUND OF THE INVENTION

BRIEF SUMMARY OF THE INVENTION

BRIEF DESCRIPTION OF THE SEVERAL VIEWS OF THE DRAWING

DETAILED DESCRIPTION OF THE INVENTION

Claims (10)

1. A coil for an electric rotating machine, comprising:

2. A coil for an electric rotating machine, comprising:

3. A coil for an electric rotating machine, comprising:

4. A coil for an electric rotating machine, comprising:

5. A coil for an electric rotating machine, comprising:

6. A coil for an electric rotating machine, comprising:

7. A coil for an electric rotating machine, comprising:

8. A coil for an electric rotating machine, comprising:

9. A coil for an electric rotating machine, comprising:

10. A coil for an electric rotating machine, comprising:

2001-04-27

2003-10-23

Coil for electric rotating machine, and mica tape and mica sheet used for the coil insulation

Expired – Lifetime

US7294788B2

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/757,788 US7507911B2

|

2001-04-27 | 2007-06-04 | Coil for electric rotating machine, and mica tape and mica sheet used for the coil insulation |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001-132940 | 2001-04-27 | ||

| JP2001132940A JP3576119B2 |

2001-04-27 | 2001-04-27 | Coil for rotating electric machine and my car tape used for insulation of this coil |

| PCT/JP2002/004033 WO2002089296A1 |

2001-04-27 | 2002-04-23 | Coil of dynamoelectric machine, and mica tape and mica sheet used to insulate this coil |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2002/004033 Continuation WO2002089296A1 |

2001-04-27 | 2002-04-23 | Coil of dynamoelectric machine, and mica tape and mica sheet used to insulate this coil |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US11/757,788 Division US7507911B2 |

2001-04-27 | 2007-06-04 | Coil for electric rotating machine, and mica tape and mica sheet used for the coil insulation |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| US20040094325A1 US20040094325A1

|

2004-05-20 |

| US7294788B2true US7294788B2

|

2007-11-13 |

2001-04-27

2003-10-23

Coil for electric rotating machine, and mica tape and mica sheet used for the coil insulation

Expired – Lifetime

US7294788B2

Family

ID=18980880

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US10/690,644 Expired – Lifetime US7294788B2

|

2001-04-27 | 2003-10-23 | Coil for electric rotating machine, and mica tape and mica sheet used for the coil insulation |

| US11/757,788 Expired – Lifetime US7507911B2

|

2001-04-27 | 2007-06-04 | Coil for electric rotating machine, and mica tape and mica sheet used for the coil insulation |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US11/757,788 Expired – Lifetime US7507911B2

|

2001-04-27 | 2007-06-04 | Coil for electric rotating machine, and mica tape and mica sheet used for the coil insulation |

Country Status (7)

| Country | Link |

|---|---|

| US (2) |

US7294788B2 |

| EP (1) |

EP1383226B2 |

| JP (1) |

JP3576119B2 |

| CN (1) |

CN1238944C |

| BR (1) |

BR0209184A |

| DE (1) |

DE60231389D1 |

| WO (1) |

WO2002089296A1 |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

US20050277721A1 * |

2004-06-15 | 2005-12-15 | Siemens Westinghouse Power Corporation | High thermal conductivity materials aligned within resins |

US20070222308A1 * |

2001-04-27 | 2007-09-27 | Katsuhiko Yoshida | Coil for electric rotating machine, and mica tape and mica sheet used for the coil insulation |

US20080029291A1 * |

2006-08-04 | 2008-02-07 | Lisa Marie Sternberg | Liquid-cooled stator bars and a method for manufacturing the same |

US20080284262A1 * |

2004-06-15 | 2008-11-20 | Siemens Power Generation, Inc. | Stator coil with improved heat dissipation |

US20110181145A1 * |

2010-01-22 | 2011-07-28 | Thomas Baumann | Conductive bar for electric machines |

US8039530B2 |

2003-07-11 | 2011-10-18 | Siemens Energy, Inc. | High thermal conductivity materials with grafted surface functional groups |

US20120169173A1 * |

2009-10-29 | 2012-07-05 | Jang Jeong Cheol | Stator for motor |

US8277613B2 |

2005-04-15 | 2012-10-02 | Siemens Energy, Inc. | Patterning on surface with high thermal conductivity materials |

US8357433B2 |

2005-06-14 | 2013-01-22 | Siemens Energy, Inc. | Polymer brushes |

US8383007B2 |

2005-06-14 | 2013-02-26 | Siemens Energy, Inc. | Seeding resins for enhancing the crystallinity of polymeric substructures |

US11791684B2 |

2020-07-02 | 2023-10-17 | Ge Aviation Systems Llc | Method and system for electrically insulating portions of an electric machine |

Families Citing this family (43)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

US7781063B2 |

2003-07-11 | 2010-08-24 | Siemens Energy, Inc. | High thermal conductivity materials with grafted surface functional groups |

JP4599063B2 * |

2004-01-15 | 2010-12-15 | 株式会社東芝 | Coil winding insulation tape |

JP4403829B2 * |

2004-02-27 | 2010-01-27 | 株式会社日立製作所 | Rotating electric machine, electrically insulated wire ring and epoxy resin composition used therefor |

US20050274774A1 * |

2004-06-15 | 2005-12-15 | Smith James D | Insulation paper with high thermal conductivity materials |

US20050277349A1 * |

2004-06-15 | 2005-12-15 | Siemens Westinghouse Power Corporation | High thermal conductivity materials incorporated into resins |

US8216672B2 |

2004-06-15 | 2012-07-10 | Siemens Energy, Inc. | Structured resin systems with high thermal conductivity fillers |

US7592045B2 |

2004-06-15 | 2009-09-22 | Siemens Energy, Inc. | Seeding of HTC fillers to form dendritic structures |

US7553781B2 |

2004-06-15 | 2009-06-30 | Siemens Energy, Inc. | Fabrics with high thermal conductivity coatings |

US7553438B2 * |

2004-06-15 | 2009-06-30 | Siemens Energy, Inc. | Compression of resin impregnated insulating tapes |

US7776392B2 |

2005-04-15 | 2010-08-17 | Siemens Energy, Inc. | Composite insulation tape with loaded HTC materials |

US7846853B2 |

2005-04-15 | 2010-12-07 | Siemens Energy, Inc. | Multi-layered platelet structure |

US7955661B2 |

2005-06-14 | 2011-06-07 | Siemens Energy, Inc. | Treatment of micropores in mica materials |

US7655295B2 |

2005-06-14 | 2010-02-02 | Siemens Energy, Inc. | Mix of grafted and non-grafted particles in a resin |

US7851059B2 |

2005-06-14 | 2010-12-14 | Siemens Energy, Inc. | Nano and meso shell-core control of physical properties and performance of electrically insulating composites |

US20070026221A1 * |

2005-06-14 | 2007-02-01 | Siemens Power Generation, Inc. | Morphological forms of fillers for electrical insulation |

JP4996086B2 * |

2005-09-29 | 2012-08-08 | 株式会社東芝 | Mica tape and rotating electric coil using this mica tape |

KR100693314B1 |

2005-09-30 | 2007-03-13 | 디피씨(주) | A transformer |

JP4675741B2 * |

2005-10-06 | 2011-04-27 | 三菱電機株式会社 | Stator coil of rotating electric machine |

US7547847B2 * |

2006-09-19 | 2009-06-16 | Siemens Energy, Inc. | High thermal conductivity dielectric tape |

US7655868B2 * |

2008-01-08 | 2010-02-02 | General Electric Company | Stator bar components with high thermal conductivity |

US20090174279A1 * |

2008-01-08 | 2009-07-09 | General Electric Company | Stator Bar Components with High Thermal Conductivity Resins, Varnishes, and Putties |

DE202010014889U1 |

2010-10-29 | 2011-02-10 | Abb Ag | Isolation material precursor and insulation material |

US10032529B2 * |

2010-12-09 | 2018-07-24 | Westinghouse Electric Company Llc | Nuclear reactor internal electric control rod drive mechanism assembly |

CN103095018A * |

2011-10-27 | 2013-05-08 | 江苏大中电机股份有限公司 | Insulating device of low-speed variable frequency motor for steel rolling |

US20140327335A1 * |

2011-11-14 | 2014-11-06 | Mitsubishi Electric Corporation | Electromagnetic coils, method of manufacturing same, and insulating tapes |

CN102364825A * |

2011-11-23 | 2012-02-29 | 哈尔滨电机厂有限责任公司 | High thermal conductivity groove fixing structure of large-scale air cooling generator stator bar |

JP5611182B2 * |

2011-12-07 | 2014-10-22 | 株式会社日立製作所 | Dry mica tape, and electrically insulated wire ring and rotating electric machine using the same |

JP5611485B1 * |

2013-01-10 | 2014-10-22 | 三菱電機株式会社 | Insulating tape, manufacturing method thereof, and stator coil |

CN103607086B * |

2013-12-02 | 2016-02-24 | 哈尔滨电气动力装备有限公司 | Large high-voltage motor bar formula bar insulation technique |

CN103757977B * |

2014-01-02 | 2016-06-08 | 雅安兴美云母工业有限责任公司 | A kind of inorganic particle mica paper and its production and use |

US10199136B2 |

2014-01-29 | 2019-02-05 | Mitsubishi Electric Corporation | Insulating tape and production method thereof, stator coil and production method thereof, and rotating electric machine |

CN104319029A * |

2014-11-17 | 2015-01-28 | 通城县中天云母制品有限公司 | Method for manufacturing calcined type fireproof mica tape |

JPWO2016104141A1 * |

2014-12-22 | 2017-04-27 | 三菱電機株式会社 | Insulating tape and manufacturing method thereof, stator coil and manufacturing method thereof, and generator |

DE102015213535A1 * |

2015-07-17 | 2017-01-19 | Siemens Aktiengesellschaft | Solid insulation material, use for this purpose and insulation system manufactured therewith |

CN106712322B * |

2015-07-23 | 2021-03-23 | 珠海格力节能环保制冷技术研究中心有限公司 | Servo motor and iron core assembly thereof |

US10671325B2 |

2015-10-28 | 2020-06-02 | International Business Machines Corporation | Selective secure deletion of data in distributed systems and cloud |

US10367391B2 * |

2016-05-17 | 2019-07-30 | Siemens Energy, Inc. | Generator stator bar having profile strip and process for manufacturing generator stator bar |

WO2019115427A1 * |

2017-12-12 | 2019-06-20 | Merck Patent Gmbh | Process for the production of a thermally conductive tape |

US11081924B2 * |

2018-06-04 | 2021-08-03 | Honeywell International Inc. | Method and apparatus to reduce losses in a compact high speed generator |

CN110394994A * |

2019-07-16 | 2019-11-01 | 西安西电电工材料有限责任公司 | A kind of moulding technique of semi-solid preparation mica products foil |

JP7292525B2 * |

2020-09-09 | 2023-06-16 | 三菱電機株式会社 | Rotating Machine Coil, Rotating Electric Machine, and Manufacturing Method of Rotating Machine Coil |

CN114188092B * |

2021-12-02 | 2022-06-28 | 浙江荣泰电工器材股份有限公司 | Processing technology of special-shaped mica insulation product |

CN115346710A * |

2022-09-14 | 2022-11-15 | 苏州巨峰电气绝缘系统股份有限公司 | High-thermal-conductivity multi-rubber powder mica tape and preparation method thereof |

Citations (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

US2320922A * |

1940-10-16 | 1943-06-01 | Westinghouse Electric & Mfg Co | High-voltage coil insulation |

JPS5553802A |

1978-10-17 | 1980-04-19 | Japan Mica Ind | Resin impregnated lumped mica basic material sheet and method of manufacturing same |

JPS58144563A |

1982-02-22 | 1983-08-27 | Mitsubishi Electric Corp | Manufacture of coil conductor |

JPS58157348A |

1982-03-10 | 1983-09-19 | Toshiba Corp | Armature coil |

JPS5928255A |

1982-08-05 | 1984-02-14 | Aiwa Co Ltd | Optical information reproducer |

US4471256A * |

1982-06-14 | 1984-09-11 | Nippon Soken, Inc. | Piezoelectric actuator, and valve apparatus having actuator |

US4806806A |

1986-10-22 | 1989-02-21 | Asea Aktiebolag | Coil for arrangement in slots in a stator or rotor of an electrical machine |

JPH01176257A |

1987-12-28 | 1989-07-12 | Nippon Maika Seisakusho:Kk | Dry mica forming material |

JPH05111206A |

1991-10-08 | 1993-04-30 | Toshiba Corp | Insulating-resin impregnated coil for high-voltage rotating machine |

JPH0945133A |

1995-08-01 | 1997-02-14 | Japan Mica Ind Co Ltd | Mica base sheet-like body and insulated coil |

JPH11213757A |

1998-01-28 | 1999-08-06 | Fuji Electric Co Ltd | Mica tape |

EP0939478A2 |

1998-02-27 | 1999-09-01 | Hitachi, Ltd. | Insulating material and winding for electrical machines |

JPH11329126A |

1998-05-13 | 1999-11-30 | Japan Mica Ind Co Ltd | Mica base material sheet and insulating coil |

US6022584A * |

1995-11-15 | 2000-02-08 | The United States Of America As Represented By The Secretary Of The Navy | Making large porous aggregates |

JP2000125499A |

1998-10-13 | 2000-04-28 | Toshiba Corp | Fixing member of insulated coil, dynamoelectric machine having the fixing member and fixing method of insulated coil |

JP2000173818A |

1998-12-02 | 2000-06-23 | Hitachi Ltd | Coil and manufacture of coil |

JP2001061247A |

1999-08-23 | 2001-03-06 | Toshiba Corp | Stator coil for rotating electric machine |

US6242825B1 * |

1998-11-25 | 2001-06-05 | Hitachi, Ltd. | Electric rotating machine with reduced thickness and volume of insulation |

US20010030022A1 * |

2000-03-17 | 2001-10-18 | Sony Chemicals Corp. | Adhesive material |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

DE277012C † |

1912-03-18 | |||

JPS4323029B1 † |

1962-03-27 | 1968-10-03 | ||

US3571491A † |

1968-08-22 | 1971-03-16 | Gen Electric | Electrical insulating compositions of polyester resin, epoxy resin, polyvinyl acetal resin and finely divided filler |

JPS4990792A † |

1972-12-30 | 1974-08-29 | ||

US4117361A † |

1975-01-10 | 1978-09-26 | Westinghouse Electric Corp. | Solventless impregnating composition |

JPS5690827A † |

1979-12-26 | 1981-07-23 | Toshiba Corp | Heat-resistant resin composition |

JPS57167374A † |

1981-04-07 | 1982-10-15 | Mitsubishi Electric Corp | Preparation of laminated mica tape |

US5618891A † |

1995-03-29 | 1997-04-08 | General Electric Co. | Solventless resin composition having minimal reactivity at room temperature |

US6359232B1 † |

1996-12-19 | 2002-03-19 | General Electric Company | Electrical insulating material and stator bar formed therewith |

US6153301A † |

1997-10-21 | 2000-11-28 | Kabushiki Kaisha Toshiba | Mica tape and insulated coil using the same |

DE19822137A1 † |

1998-05-16 | 1999-11-18 | Asea Brown Boveri | High voltage insulated stator winding |

JP2908431B1 |

1998-05-29 | 1999-06-21 | 株式会社東芝 | Manufacturing method of electrical insulation coil |

US6555617B1 † |

1999-07-29 | 2003-04-29 | Mitsubishi Chemical Corporation | Composition of cyclic anhydride modified polyvinyl acetal and curable resin and laminated products |

JP2001105546A † |

1999-07-30 | 2001-04-17 | Mitsubishi Chemicals Corp | Laminate |

US6190775B1 † |

2000-02-24 | 2001-02-20 | Siemens Westinghouse Power Corporation | Enhanced dielectric strength mica tapes |

JP3576119B2 * |

2001-04-27 | 2004-10-13 | 株式会社東芝 | Coil for rotating electric machine and my car tape used for insulation of this coil |

- 2001

- 2001-04-27

JP

JP2001132940A

patent/JP3576119B2/en

not_active

Expired – Lifetime

- 2001-04-27

- 2002

- 2002-04-23

DE

DE60231389T

patent/DE60231389D1/en

not_active

Expired – Lifetime - 2002-04-23

BR

BR0209184-4A

patent/BR0209184A/en

not_active

Application Discontinuation - 2002-04-23

EP

EP02718644.4A

patent/EP1383226B2/en

not_active

Expired – Lifetime - 2002-04-23

WO

PCT/JP2002/004033

patent/WO2002089296A1/en

active

Application Filing - 2002-04-23

CN

CNB02808974XA

patent/CN1238944C/en

not_active

Expired – Lifetime

- 2002-04-23

- 2003

- 2003-10-23

US

US10/690,644

patent/US7294788B2/en

not_active

Expired – Lifetime

- 2003-10-23

- 2007

- 2007-06-04

US

US11/757,788

patent/US7507911B2/en

not_active

Expired – Lifetime

- 2007-06-04

Patent Citations (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

US2320922A * |

1940-10-16 | 1943-06-01 | Westinghouse Electric & Mfg Co | High-voltage coil insulation |

JPS5553802A |

1978-10-17 | 1980-04-19 | Japan Mica Ind | Resin impregnated lumped mica basic material sheet and method of manufacturing same |

JPS58144563A |

1982-02-22 | 1983-08-27 | Mitsubishi Electric Corp | Manufacture of coil conductor |

JPS58157348A |

1982-03-10 | 1983-09-19 | Toshiba Corp | Armature coil |

US4471256A * |

1982-06-14 | 1984-09-11 | Nippon Soken, Inc. | Piezoelectric actuator, and valve apparatus having actuator |

JPS5928255A |

1982-08-05 | 1984-02-14 | Aiwa Co Ltd | Optical information reproducer |

US4806806A |

1986-10-22 | 1989-02-21 | Asea Aktiebolag | Coil for arrangement in slots in a stator or rotor of an electrical machine |

JPH01176257A |

1987-12-28 | 1989-07-12 | Nippon Maika Seisakusho:Kk | Dry mica forming material |

JPH05111206A |

1991-10-08 | 1993-04-30 | Toshiba Corp | Insulating-resin impregnated coil for high-voltage rotating machine |

JPH0945133A |

1995-08-01 | 1997-02-14 | Japan Mica Ind Co Ltd | Mica base sheet-like body and insulated coil |

US6022584A * |

1995-11-15 | 2000-02-08 | The United States Of America As Represented By The Secretary Of The Navy | Making large porous aggregates |

JPH11213757A |

1998-01-28 | 1999-08-06 | Fuji Electric Co Ltd | Mica tape |

EP0939478A2 |

1998-02-27 | 1999-09-01 | Hitachi, Ltd. | Insulating material and winding for electrical machines |

US6069430A * |

1998-02-27 | 2000-05-30 | Hitachi, Ltd. | Insulating material and windings thereby |

JPH11329126A |

1998-05-13 | 1999-11-30 | Japan Mica Ind Co Ltd | Mica base material sheet and insulating coil |

JP2000125499A |

1998-10-13 | 2000-04-28 | Toshiba Corp | Fixing member of insulated coil, dynamoelectric machine having the fixing member and fixing method of insulated coil |

US6242825B1 * |

1998-11-25 | 2001-06-05 | Hitachi, Ltd. | Electric rotating machine with reduced thickness and volume of insulation |

JP2000173818A |

1998-12-02 | 2000-06-23 | Hitachi Ltd | Coil and manufacture of coil |

JP2001061247A |

1999-08-23 | 2001-03-06 | Toshiba Corp | Stator coil for rotating electric machine |

US20010030022A1 * |

2000-03-17 | 2001-10-18 | Sony Chemicals Corp. | Adhesive material |

Also Published As

| Publication number | Publication date |

|---|---|

EP1383226A4 |

2005-04-27 |

JP3576119B2 |

2004-10-13 |

US20070222308A1 |

2007-09-27 |

WO2002089296A1 |

2002-11-07 |

BR0209184A |

2004-08-03 |

EP1383226B2 |

2014-12-24 |

CN1238944C |

2006-01-25 |

US20040094325A1 |

2004-05-20 |

DE60231389D1 |

2009-04-16 |

EP1383226B1 |

2009-03-04 |

CN1505863A |

2004-06-16 |

JP2002330562A |

2002-11-15 |

US7507911B2 |

2009-03-24 |

EP1383226A1 |

2004-01-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

|

US7294788B2 |

Coil for electric rotating machine, and mica tape and mica sheet used for the coil insulation | |

|

US6426578B1 |

Electric rotating machine | |

|

US7574790B2 |

Method for manufacturing a stator of an electrical rotating machine | |

|

US7120993B2 |

Method of manufacturing insulated coil | |

|

CN1317719C |

Insulating material and machine winding | |

|

EP0266602A1 |

Coil for electrical machines and method of manufacturing the coil | |

|

GB2456373A |

Stator bar components with high thermal conductivity resins, varnishes, and putties | |

|

JP2012244861A |

Insulation coil | |

|

JP3653901B2 |

Rotator stator coil | |

|

JP2007282410A |

Rotating electric machine, stator coil thereof, its manufacturing method, and semiconductive sheet, semiconductive tape | |

|

ZA200108545B |

Improvements in electrical machines. | |

|

JP2000058314A |

High temperature conductive coil and insulating sheet and manufacture thereof | |

|

JP2001061247A |

Stator coil for rotating electric machine | |

|

JP2000173818A |

Coil and manufacture of coil | |

|

JP2023092752A |

Prepreg mica tape, rotary electric machine, and manufacturing method for rotary electric machine | |

|

JP7498098B2 |

Prepreg mica tape, rotating electric machine, and method for manufacturing rotating electric machine | |

| New high voltage insulation with increased thermal conductivity | ||

|

JP2024101033A |

Prepreg mica tape, dynamo-electric machine and manufacturing method of dynamo-electric machine | |

|

JPS62125838A |

Water cooling winding for electromagnetic stirring apparatus | |

|

JPH04197056A |

Coil insulating part of electric rotating machine | |

| Development of Polymer-Ceramic Composite Materials for the Winding Insulation of Highly Utilized and Energy-Efficient Electrical Machines | ||

|

JPS63161863A |

Superconducting winding | |

|

JPS63117639A |

Insulating method for slot of core for rotary electric machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AS | Assignment | Owner name: KABUSHIKI KAISHA TOSHIBA, JAPAN Free format text: Effective date: |

|

| STCF | Information on status: patent grant | Free format text: PATENTED CASE |

|

| CC | Certificate of correction | ||

| FPAY | Fee payment | Year of fee payment: 4 |

|

| FPAY | Fee payment | Year of fee payment: 8 |

|

| MAFP | Maintenance fee payment | Free format text: PAYMENT OF MAINTENANCE FEE, 12TH YEAR, LARGE ENTITY (ORIGINAL EVENT CODE: M1553); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY Year of fee payment: |