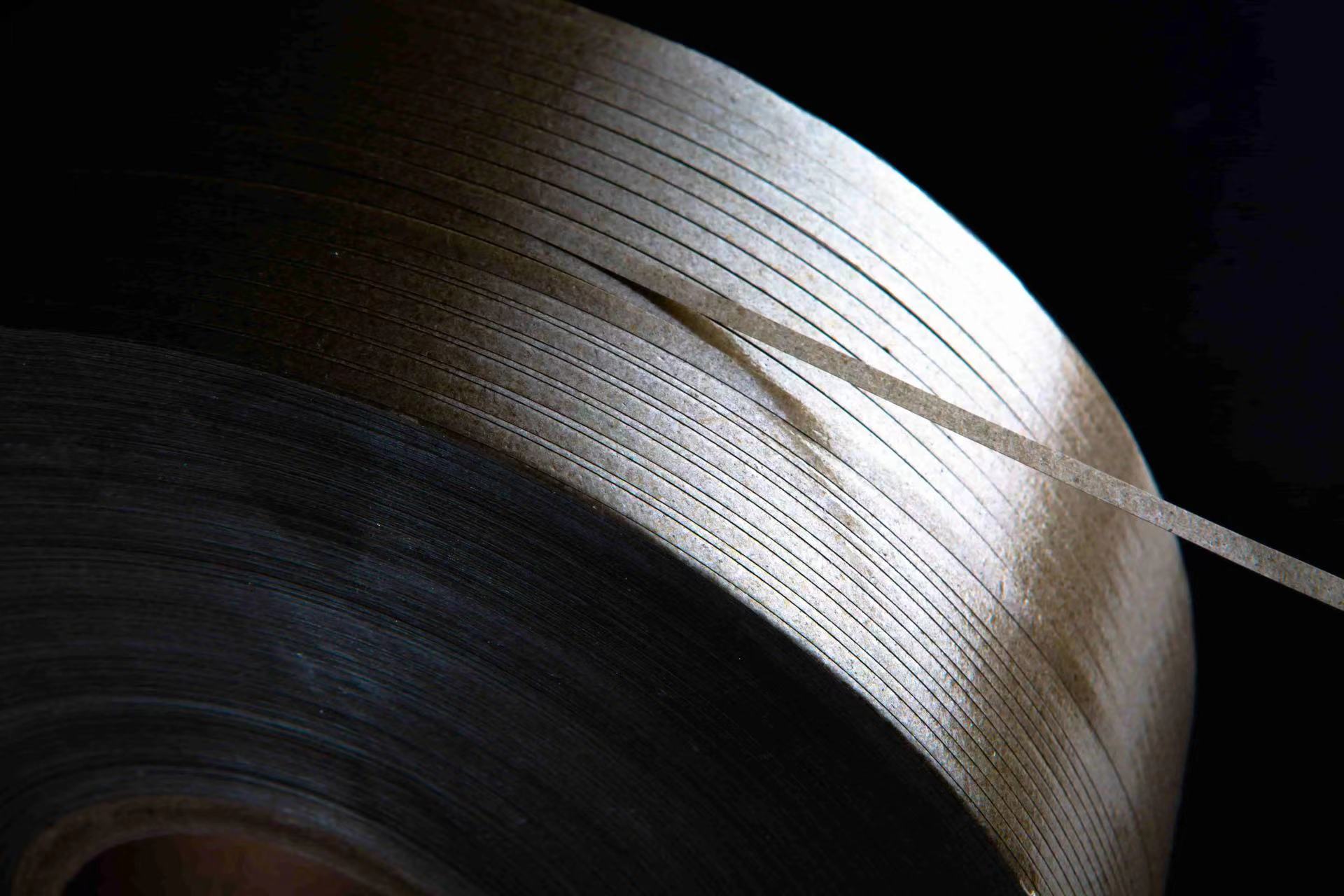

What is synthetic mica tape? Characteristics of synthetic mica tape

Synthetic mica is a synthetic material that is made by replacing the hydroxyl group with fluoride ions under normal pressure conditions. It has a large size and complete crystal structure. Synthetic mica tape is mica paper made of synthetic mica as the main material, and then glass cloth is attached to one or both sides using adhesive. The glass cloth attached to one side of the mica paper is called “single-sided adhesive tape”, and the glass cloth attached to both sides is called “double-sided adhesive tape”. In the manufacturing process, several structural layers are bonded together, then dried, rolled up, and cut into tapes of different specifications.

In addition to the characteristics of natural mica tape, namely: small expansion coefficient, high dielectric strength, high electrical resistance, and uniform dielectric constant, the main characteristic of synthetic mica tape is its heat resistance, which contains no crystalline water and has a melting point of 1,375℃, ensuring high safety margins and the best high temperature performance, reaching Class A fire resistance level (950-1000℃).

Synthetic mica tape can withstand temperatures above 1000℃ and has a thickness range of 0.08-0.15mm, with a maximum supply width of 920mm.

- Double-sided synthetic mica tape: a fire-resistant wire and cable made of synthetic mica paper as the base material, glass fiber cloth as the double-sided reinforcement material, and bonded with a silicone resin adhesive. It is the ideal choice of material with the best fire resistance, recommended for key engineering projects.

- Single-sided synthetic mica tape: a material for manufacturing fire-resistant wire and cable, with synthetic mica paper as the base material and glass fiber cloth as the single-sided reinforcement material. It has good fire resistance and is recommended for key engineering projects.

Precautions for the use of synthetic mica tape

There are always precautions for using any material, and synthetic mica tape is no exception. Generally, the following should be noted during storage and use:

- The storage environment should be dry and ventilated, and the effective storage period is 6 months;

- Do not get wet during transportation;

- In case of humid weather, pay attention to packaging. After opening the box, pack the remaining mica tape to prevent dust or moisture;

- Do not drag the mica tape on the ground to prevent pollution or damage. The winding tension should be evenly controlled, to avoid loose winding or tight rupture, ensuring smooth and not falling off;

- When joining mica tape, use a thin adhesive tape to prevent the outer diameter of the joint from being too large, which will affect the extruded insulation;

- According to the outer diameter of the conductor and the width of the mica tape, select a suitable winding angle and overlap rate. The winding angle is generally 40% to 50%, and the overlap rate is generally 30% to 50%;

- After winding each spool of the conductor, and before extruding the insulation, pack it with suitable packaging materials to prevent the entry of dust, moisture, or damage during transportation and handling.

Other safety precautions should also be taken according to different usage environments.